產品應用

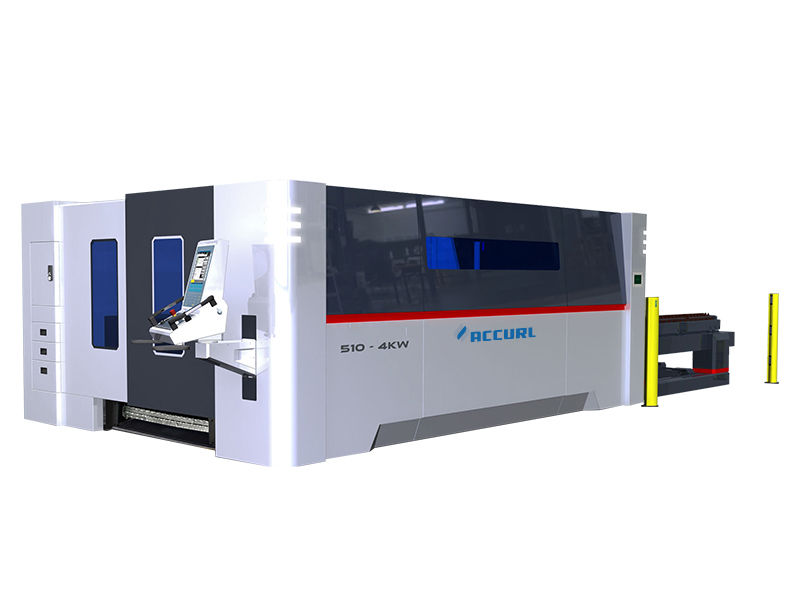

F3015 具有 1500 毫米 x3000 毫米的工作區域,是 ACCURL3015 的基本和最經濟的型號。廣泛應用於廣告板加工、金屬板結構、高壓/低壓電器櫃製作、紡織機械零件、廚具、汽車、機械、電梯、電器零件、彈簧捲片、地鐵線路零配件等。

ACCURL3015 規範 光纖激光金屬切割機 | |||

激光頭 | BodorGenius 自動對焦激光頭 | ||

激光光源 | IPG/創鑫 | ||

工作區域 | 1500 *3000毫米 | ||

激光功率 | 500w/700w/800w/1000w/1500w/2000w/2500w/3000w/4000w | ||

冷卻方式 | 水冷 | ||

控制系統 | BodorPro | ||

最大切割速度 | 35米/分鐘 | ||

精確 | 位置精度:0.03mm。重定位精度:0.02mm | ||

驅動系統 | 日本安川伺服電機 | ||

傳輸 | 台灣上銀HIWIN方軌,台灣YYC齒條 | ||

軸承 | 日本NSK軸承 | ||

電器元件 | 法國施耐德電器元件 | ||

氣動元件 | 日本SMC氣動元件 | ||

機器尺寸+重量 | 4550*2300*2000mm , 包裝後 , 重量 3000kg | ||

最大加速度 | 1.5G | ||

其他部分 | 自動潤滑系統+壓力表+激光護目鏡+WIFI控制+控制面板等。 | ||

主要特點

1.優異的路徑質量:更小的激光點,高工作效率,高品質。

2.切割速度快:切割速度是同功率CO2激光切割機的2-3倍。

3.穩定運行:採用世界頂級進口光纖激光器,性能穩定,關鍵部件可達10萬小時;

4.光電轉換效率高:與CO2激光切割機相比,光纖激光切割機具有三倍的光電轉換效率。

5.低成本:節約能源,保護環境。光電轉換率高達25-30%。電耗低,僅為傳統CO2激光切割機的20%-30%左右。

6.低維護:光纖線路傳輸無需反射鏡頭,節省維護成本;

7.操作簡便:光纖線路傳輸,光路無需調整。

快速詳情

條件:新的

激光類型:光纖激光器

適用材料:金屬

切割厚度:取決於

切割面積:1500x3000mm

切割速度:500mm/s

CNC或不:是的

冷卻模式:水冷

控制軟件:BodorPro

支持的圖形格式:AI,BMP,DXF,PLT

認證:CCC、CE、ISO、SGS、UL

提供售後服務:工程師可在海外維修機械

關鍵詞:熱銷金屬激光切割機

切割厚度:0-30mm

位置精度:0.02mm

切割速度:0-10000mm/min

切割材料:金屬不銹鋼碳鋼鋁

應用:鋁板

虎鉗動作方式:半自動夾鉗

動力:機械

品牌: 博多

行業:珠寶金屬製品汽車零部件

機械零件

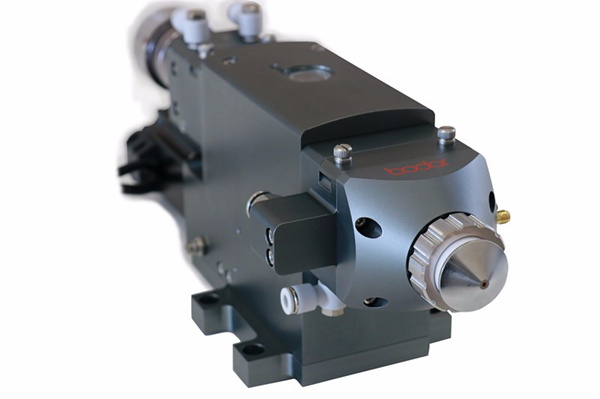

名稱: BodorGenius 自動對焦激光頭

1、自動對焦

適用於各種焦距,由機床控制系統控制。在切割過程中將自動調整焦點,以實現不同厚度金屬板的最佳切割效果。

2、解放雙手

焦距由操作系統控制。無需人工調節,有效避免人工操作造成的錯誤或故障。

3、快速

(1)自動對焦會在沖切過程中自動調整最合適的焦點,大大提高了切割速度;

(2)更換不同材料或不同厚度的板材時,手動調焦激光頭需要人工調節,費力費時;自動聚焦激光頭由控制系統控制,可自動讀取系統存儲參數,節省時間和人力;

(3)准直保護鏡抽屜可以更好地保護准直鏡,提高保護鏡更換速度。

4、精度

增加穿孔焦距,分別設置穿孔焦距和切割焦距,提高切割精度。

5、經久耐用

(1)內置雙水冷結構,保證准直、聚焦元件恆溫,避免鏡片過熱損壞,冷卻效果更佳,長期切割不發熱、不起霧,延長鏡片使用壽命。

(2)增加准直保護鏡和聚焦保護鏡,精心保護關鍵部件。

名稱: 一體式鑄造機機身

採用片狀石墨鑄鐵,最低抗拉強度為200MPa。含碳量高,抗壓強度高,硬度高。減震性和耐磨性強。較低的熱敏度和床隙敏感度降低了設備在使用過程中的損耗,因此機器精度可以長期保持,並且在整個生命週期中不變形。

名稱: 控制櫃

機櫃集成了激光源和所有電子機器部件,可以保護貴重的電子部件和昂貴的激光源。機櫃內的風扇為電氣部件提供更好的冷卻系統

名稱: 自動潤滑系統

電潤滑是一種結構合理、性能優良、功能全面的齒輪泵。

潤滑系統通過與主機程序控制系統連接,可監控油箱內油位和輸油壓力,設置潤滑週期,有效防止潤滑系統生鏽,保證切割精度。